The Best Fluffy Pancakes recipe you will fall in love with. Full of tips and tricks to help you make the best pancakes.

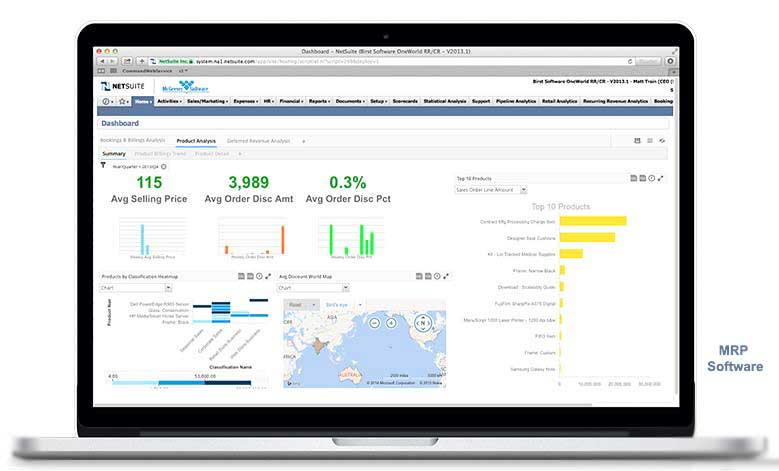

Importance of MRP Software

In today’s competitive manufacturing landscape, organizations face increasing pressure to minimize costs, maximize productivity, and deliver high-quality products on time. MRP software plays a crucial role in helping businesses achieve these objectives by providing real-time visibility into inventory levels, production schedules, and supply chain activities.

Key Features of MRP Software

Inventory Management

MRP software helps organizations maintain optimal inventory levels by tracking stock levels, monitoring demand fluctuations, and generating accurate forecasts. By minimizing excess inventory and stockouts, businesses can reduce carrying costs and improve cash flow.

Production Planning and Scheduling

MRP software enables organizations to create detailed production plans and schedules based on demand forecasts, resource availability, and lead times. By optimizing production processes and minimizing downtime, businesses can enhance efficiency and meet customer delivery deadlines.

Material Procurement

MRP software automates the procurement process by generating purchase orders, tracking supplier performance, and managing supplier relationships. By streamlining the procurement process, organizations can minimize lead times, reduce costs, and ensure timely delivery of materials.

Bill of Materials (BOM) Management

MRP software maintains comprehensive databases of bill of materials, containing detailed information about components, raw materials, and subassemblies required for production. By managing BOMs effectively, organizations can ensure accurate costing, minimize errors, and maintain product quality.

Benefits of MRP Software

Improved Efficiency

MRP software streamlines manufacturing processes, reduces manual effort, and eliminates redundant tasks, leading to improved efficiency and productivity. By automating repetitive tasks such as data entry and inventory tracking, businesses can focus on value-added activities that drive business growth.

Enhanced Accuracy

MRP software provides real-time visibility into inventory levels, production schedules, and material requirements, enabling organizations to make informed decisions based on accurate and up-to-date information. By minimizing errors and discrepancies, businesses can improve decision-making and customer satisfaction.

Cost Savings

MRP software helps organizations optimize inventory levels, minimize stockouts, and reduce carrying costs, leading to significant cost savings. By identifying cost-saving opportunities and optimizing resource utilization, businesses can improve profitability and competitiveness in the market.

Better Customer Service

MRP software enables organizations to respond quickly to customer demands, fulfill orders on time, and provide accurate delivery estimates. By improving order fulfillment processes and reducing lead times, businesses can enhance customer satisfaction and loyalty.

Challenges in Implementing MRP Software

Data Accuracy and Integrity

Ensuring the accuracy and integrity of data is essential for the successful implementation of MRP software. Inaccurate or incomplete data can lead to errors in planning, scheduling, and procurement, undermining the effectiveness of MRP systems.

Integration with Existing Systems

Integrating MRP software with existing systems such as ERP, CRM, and accounting software can be challenging due to compatibility issues and data migration complexities. Seamless integration is crucial for data consistency and process efficiency across the organization.

User Adoption and Training

User adoption is critical for the success of MRP software implementation. Providing comprehensive training and support to users is essential for ensuring that they understand the benefits of the system and use it effectively to improve productivity and performance.

Customization and Configuration

Customizing and configuring MRP software to meet the specific needs and workflows of the organization requires careful planning and expertise. Organizations must ensure that the software is tailored to their unique requirements while maintaining compatibility with industry standards and best practices.

Future Trends in MRP Software

Cloud-Based Solutions

Cloud-based MRP software offers scalability, flexibility, and accessibility compared to on-premises alternatives. By migrating to the cloud, organizations can reduce infrastructure costs, improve collaboration, and access real-time data from anywhere, at any time.

Advanced Analytics and Predictive Modeling

Advanced analytics and predictive modeling capabilities are becoming increasingly important in MRP software. By leveraging AI and machine learning technologies, organizations can analyze historical data, predict future demand, and optimize production processes proactively.

Internet of Things (IoT) Integration

Integration with IoT devices enables MRP software to collect real-time data from sensors and machines on the shop floor. By monitoring equipment performance, detecting anomalies, and predicting maintenance needs, organizations can minimize downtime and optimize production efficiency.

Mobile Applications

Mobile applications enable users to access MRP software from smartphones and tablets, allowing them to view inventory levels, track production progress, and respond to alerts on the go. By providing mobile access to critical information, businesses can improve decision-making and responsiveness.

Conclusion

MRP software plays a vital role in helping manufacturing companies optimize production processes, manage inventory efficiently, and meet customer demand effectively. By automating key tasks such as inventory management, production planning, and procurement, MRP software enables organizations to improve efficiency, accuracy, and cost-effectiveness. Despite challenges such as data accuracy, integration, and user adoption, the future of MRP software is promising, with advancements in cloud computing, advanced analytics, IoT integration, and mobile applications poised to reshape the MRP landscape and drive innovation.

FAQs

- What is MRP software? MRP software, or Material Requirements Planning software, is a tool used by manufacturing companies to plan, schedule, and control production processes, manage inventory, and meet customer demand effectively.

- What are the key features of MRP software? Key features of MRP software include inventory management, production planning and scheduling, material procurement, and bill of materials (BOM) management, aimed at optimizing manufacturing operations and resource utilization.

- What are the benefits of MRP software? Benefits of MRP software include improved efficiency, enhanced accuracy, cost savings, and better customer service, enabling organizations to optimize production processes, minimize costs, and meet customer demands effectively.

- What are some challenges in implementing MRP software? Challenges in implementing MRP software include data accuracy and integrity issues, integration with existing systems, user adoption and training concerns, and customization and configuration complexities.

- What are some future trends in MRP software? Future trends in MRP software include cloud-based solutions, advanced analytics and predictive modeling, IoT integration, and mobile applications, which are poised to reshape the MRP landscape and drive innovation in manufacturing.